Prince Panacea® Technology

Replacement Membrane Cell Gasket Systems

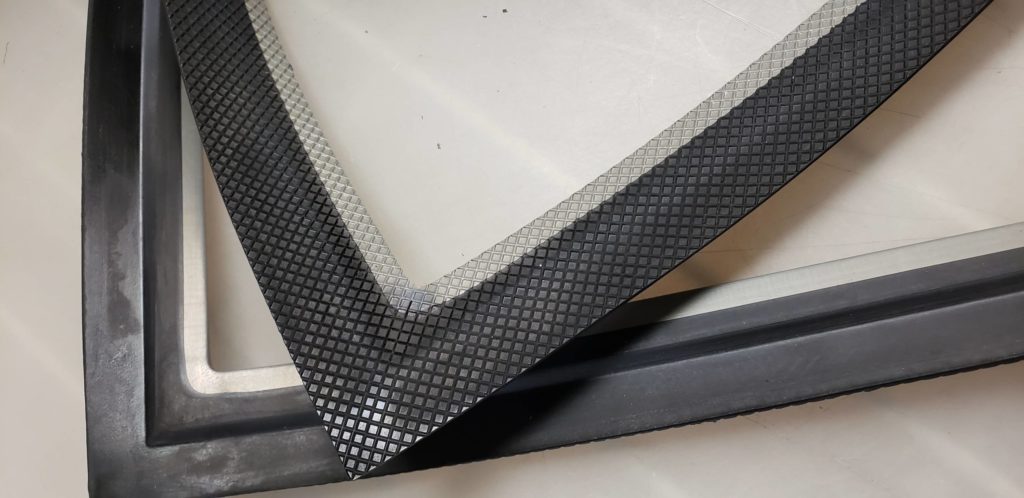

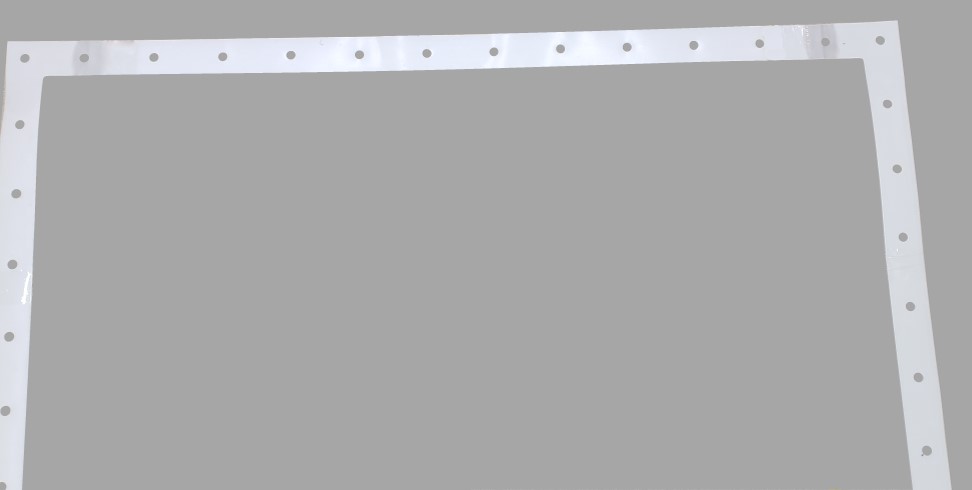

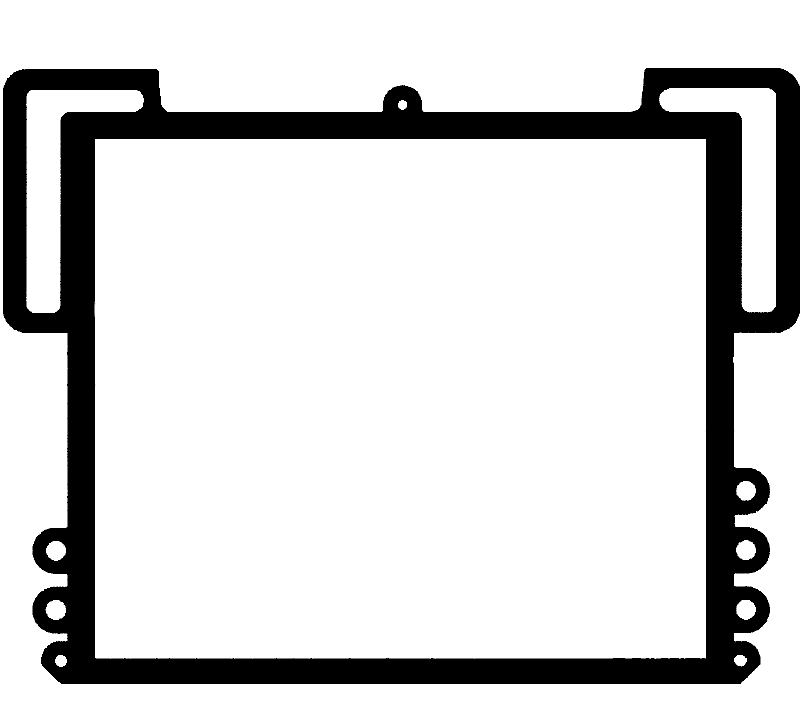

Molded Replacement Gaskets for popular Chlor-Alkali electrolyzers are advanced by Prince’s technology of using Panacea® proprietary rubber compounds that increase the life of the gasket. Prince has advanced methods of increasing the reliability of the fluoroplastic shields, including via vulcanization, and supplemented by developing unique adhesion and etching techniques.

Panacea® Elastomers

Prince’s high-performance elastomeric compounds excel in chemical resistance, temperature range, and long-term sealing ability, while formulated without the use of calcium and magnesium, that can contaminate Chlor-Alkali membranes.

Fluoroplastic

Prince manufactures many membrane cell gaskets with a fluoroplastic protection to extend the life of the gasket. This is often specified on the anode gasket, which experiences more difficult chemical conditions.

Prince Advancements

- Each Replacement Frame Gasket Type has their own individual compounds used, specifically developed by Prince for that technology.

- Prince can secure the fluoroplastic shield to the elastomer with: a fluoroplastic thread, cold-bonding with adhesive, and/or hot-bonding via vulcanization.

- A continuous fluoroplastic armoring extends gasket life.

- In some cases, Prince has incorporated the use of an EPDM “Skin” over the fluoroplastic film that contacts the Titanium anode frame, which helps to prevent fluorine-induced crevice corrosion on the Titanium frame (BiTAC®, ML32®, and NBZ types).

Trademarks respectively as listed:

INEOS Chlor Ltd. • Lurgi GmbH • Asahi KASEI Chemicals Corp. • tkUCE GmbH