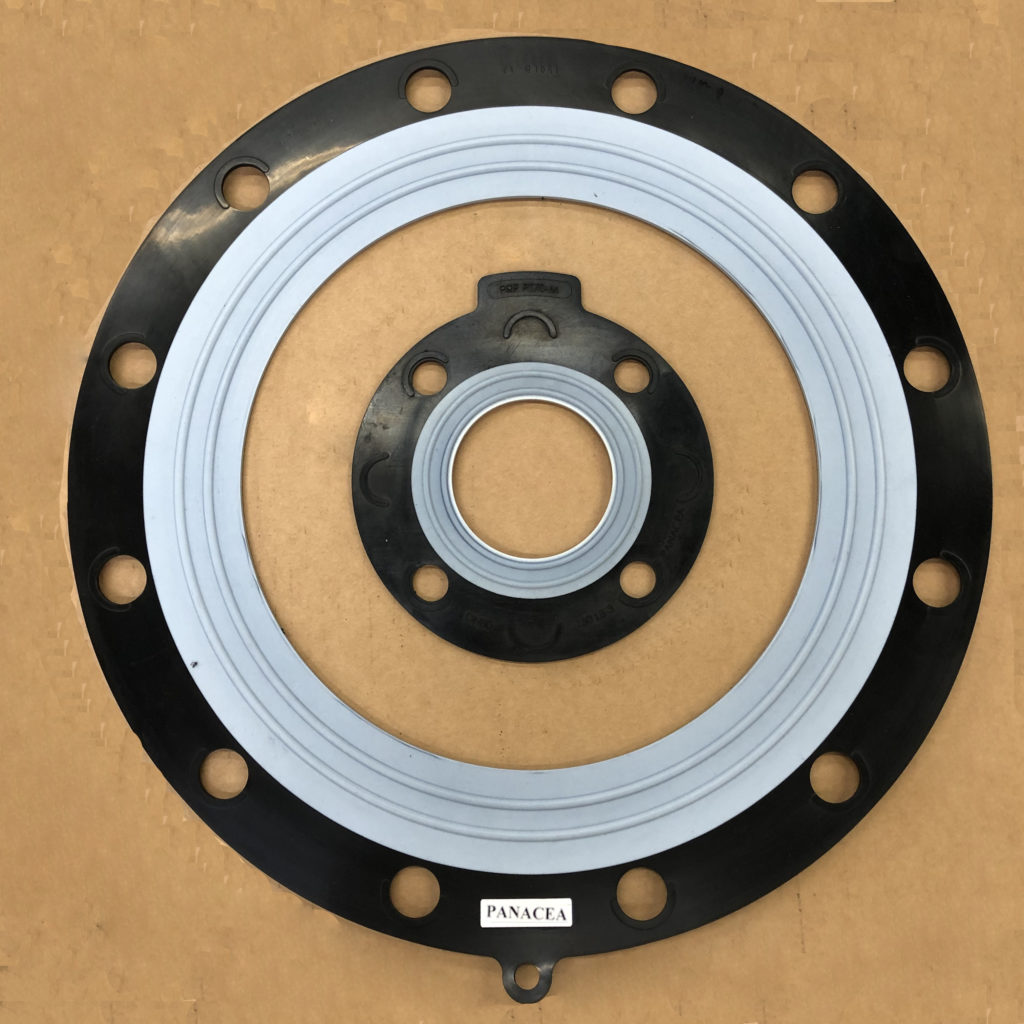

Panacea® Gasketing

PT70-M

“EASY TO SEAL” PTFE PROTECTED EPDM GASKETS

Features and Benefits

- Molded Style

- Fits ANSI 150 lb. Flanged Joints.

- These gaskets are also compatible with many DN style flange assemblies, simply by altering bolt hole location. This has been proven by many European customers, for example.

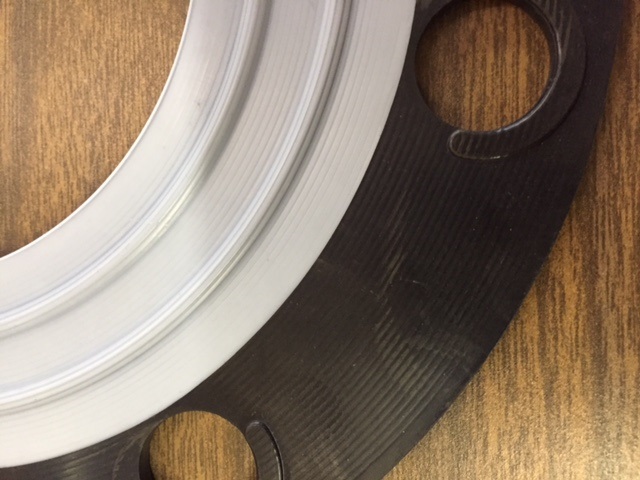

- Virgin PTFE Sealing Surface

- Almost universal chemical resistance.

- Non-contaminating for High Purity application.

- PTFE Bonded to EPDM

- -30°C (-22°F) to 150°C (300°F) continuous service temperature range.

- Bonded PTFE has no loose “ears” to interfere with the installation between flanges.

- EPDM “memory” gives long sealing life.

- Molded Dual-Seal Design

- Low Bolt torque required to seal.

- 2 seals: Primary and Secondary

- PT70 M gaskets are specified exclusively by many chemical manufacturing and processing sites, including for metallic and non-metallic piping.

- PT70 M gaskets can be re-used in many instances – please consult Prince Rubber and Plastics for details.

- Sealing ribs are able to rebound, nearly entirely, in many cases, after being taken out of compression.

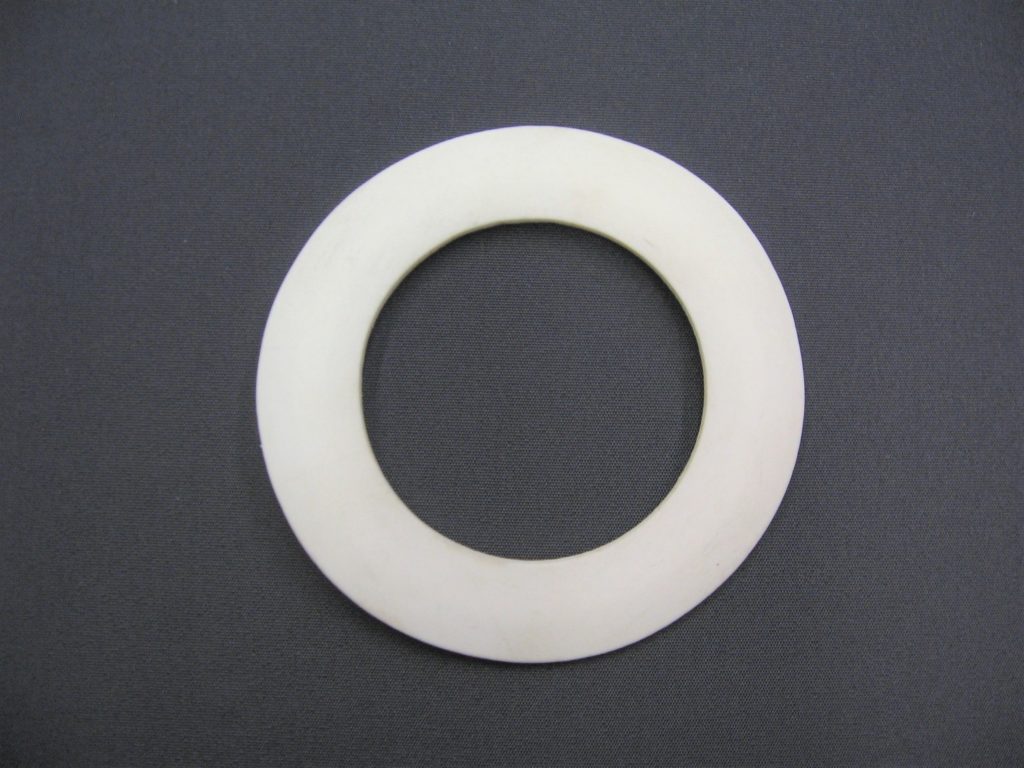

PTG White

Reinforced Fluoroplastic Gasketing Material for Temperatures up to 500°F / 260°C

Prince’s PT-G White PTFE Gasketing Compound with bead reinforcing:

- The bead reinforcing enables long-term sealing, whereas standard PTFE sheet material tends to creep perpendicularly from flange loading, and then leaks.

- Displays light flange loading in temperatures from -300ºF/-184ºC up to 500ºF/260ºC.

- Exhibits a low creep factor under pressure.

- Easily removed from flanges.

- Resistance to permanent set.

- Formable on uneven or warped flanged faces.

- Maximum sheet size: 60” x 60” (1524 mm x 1524 mm); thickness is 1/8” (3.2 mm) only