Prince – Longtime Distributor of PolyProcessing Polymeric Storage Tanks, Made in the USA

Prince has sold internationally PolyProcessing (PPC) Storage Tanks for decades, particularly to the water treatment and chemical manufacturing industries.

Advantages of PPC’s XLPE Tanks:

XLPE (Cross-Linked Polyethylene) Material Advantages

- https://www.polyprocessing.com/innovations/high-density-crosslinked-polyethylene/

- Increased durability, UV-resistance, longer life, and much lower maintenance than LDPE (Low-Density Polyethylene)

- Increased durability, lower cost, and lower maintenance than FRP (Fiberglass) Tanks

PLEASE VIEW THE DURABILITY DROP TEST:https://www.youtube.com/watch?

IMFO® Flange Option

Traditional tank maintenance can be a challenge with many chemicals – the IMFO (Integrally-Molded Flanged Outlet) Flange helps to minimize maintenance of these tanks.

- https://www.polyprocessing.com/innovations/imfo/

- Since the flange is at the bottom of the tank, full drainage is achieved below the tank knuckle radius, which can eliminate the need to enter the tank for cleaning.

- One-piece construction enhances long-term performance of the tank, since it doesn’t compromise the tank hoop’s integrity or structural design.

- The IMFO’s design brings you the highest amount of static head pressure, which contributes to the highest net positive head suction (NPHS) of any vertical non-coned tank.

- Please note that the IMFO flange protrudes slightly beneath the bottom of the tank. The tank base will need to sit on a slightly-elevated platform (usually concrete), if the IMFO flange option is of interest.

Warranty

Five years for most chemical services. PPC stands behind their warranties and products. PPC’s XLPE tanks can achieve up to 25-30 year life, and beyond.

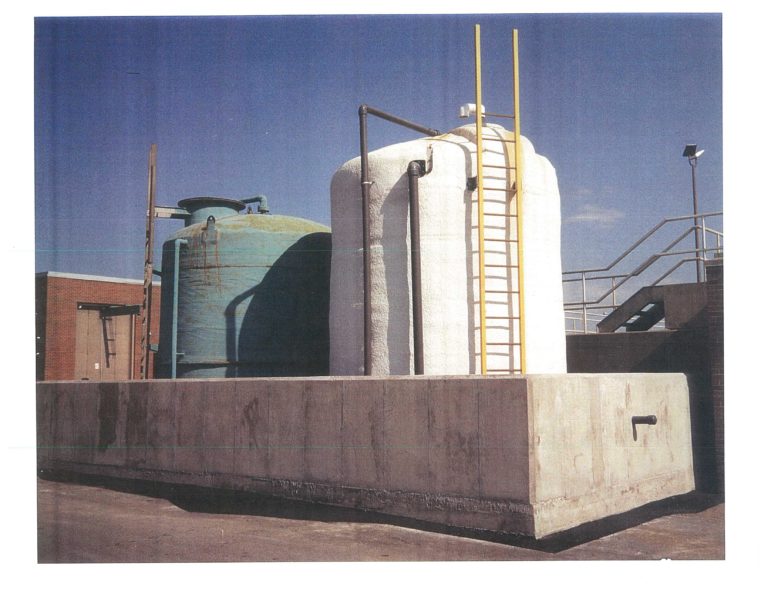

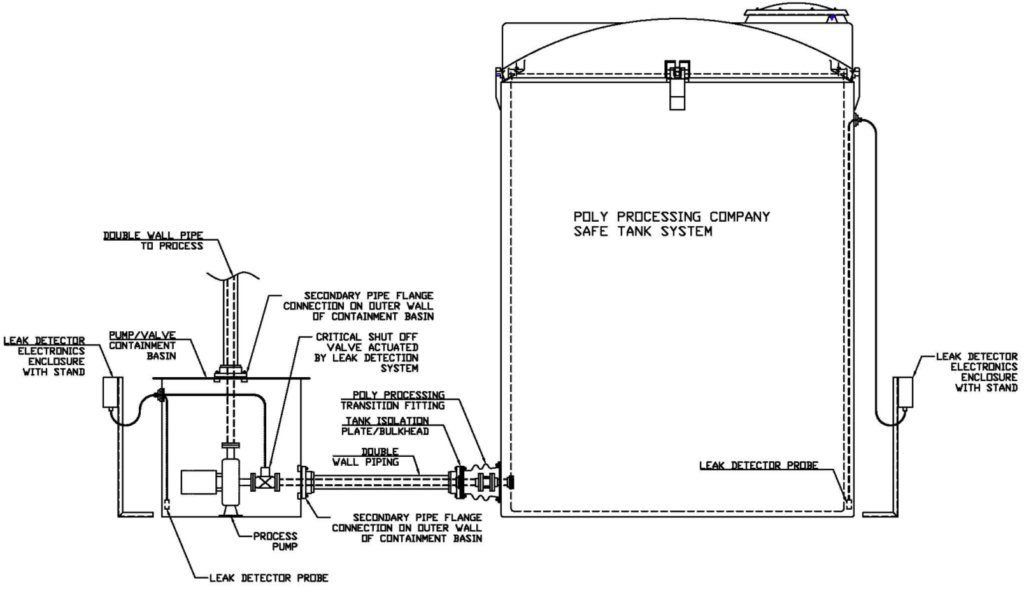

SAFE-Tank® Double Wall Tank System Option

- https://blog.polyprocessing.

com/blog/double-wall-storage- tanks - SAFE-Tank® is a “tank-within-a-tank” to safely store chemicals. The SAFE-Tank provides a minimum of 110% secondary containment by enclosing the primary storage tank within a sealed outer tank. Any chemical leak in the inner tank is fully contained in the outer shell.

- Prevents damage and injury from chemical exposure without the need for an additional containment unit.

- Offers superior protection against hazardous chemical spills for personnel and the environment.

- Alternatively, a separate secondary containment basin can be used.

OR-1000 Tank Liner Option

OR-1000 is an over-molded Polyethylene liner on the tank interior to further provide a corrosion barrier to protect the XLPE structural body, which can increase the tank’s warranty period.

Tank Volume: Up to ≈15,000 Gallon Capacity (for Vertical Tanks)

Visit https://www.polyprocessing.