Rubber Manufacturing and Fabrication

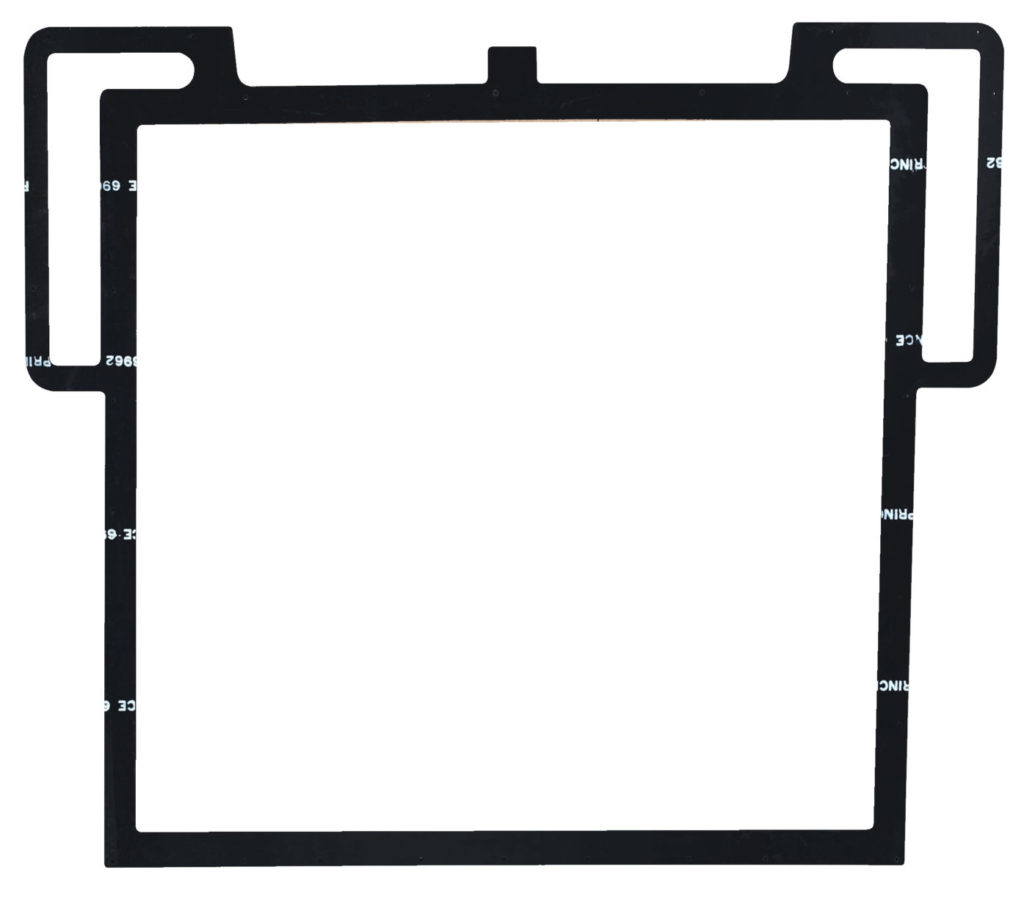

Gasket Fabrication

Prince’s Unique Panacea® Compounds for the Chemical Industry:

- 69-Series Special EPDM

- 5170 Special Pure Gum

- R3400, PP340 Vinyls

- Fluoropolymer-Protected Elastomer

- PT70-M Special PTFE-Protected EPDM

- PT-G White Reinforced PTFE

- 1475 TFE-P Fluoroelastomer

Commercial Materials:

Natural Rubber, Silicone, *Viton®, Butyl, Nitrile, Neoprene, EPDM, SBR, Expanded PTFE, etc.

*Trademark: Chemours Co.

Prince’s Unique Panacea® Compounds for the Chemical Industry:

- Extruded

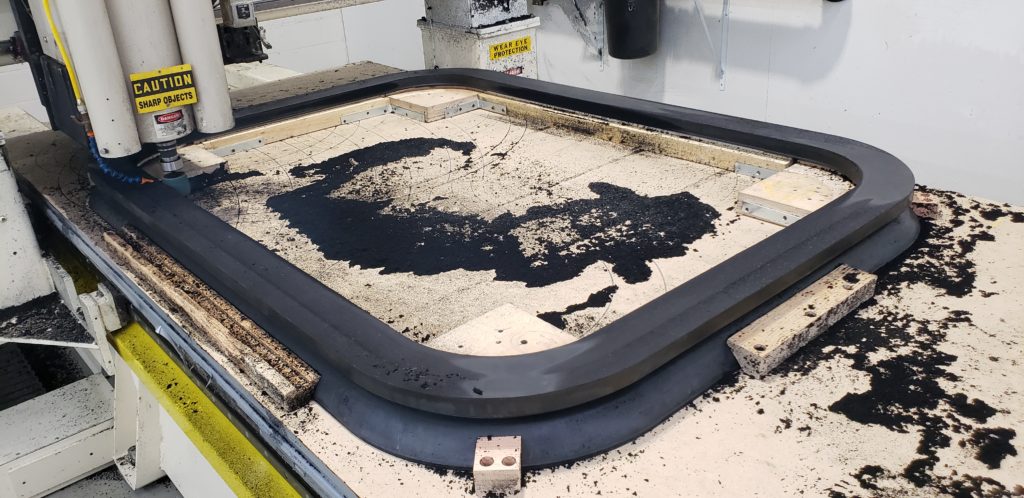

- Large Custom-Molded Gaskets:

- Up to 149.6” L (3800 mm) x 71 ¼” W (1800 mm)

- Heat-Spliced

- Machined

- Armored Fluoroplastic

- Segmented

- Dovetailed Gaskets Prince has fabricated up to 10’-diameter, with capability to go even larger.

- Molded and Vulcanized

Molded, Extruded, and Fabricated Rubber Parts

Molded and Fabricated:

Grommets, Bumpers, Plugs, Stoppers, etc., within a complete spectrum of elastomers. We mold in a size range: <1/8” up to large molded parts. Parts are produced to standard commercial or custom tolerances.

Extruded:

Cords of “U” Channels, Square, Rectangle, Bulb, etc. are produced daily, in a variety of materials, hardnesses, and applications.

Materials:

Commercial and Specialty Elastomers, and Dual-Molding

Secondary Fabrication:

Drilling, Splicing, Punching, Grinding, Adhesive-Backed

Die-Cut Gaskets:

Custom Die-Cutting of Various Thicknesses of Rubber Sheet

Rubber Tubing and Hose

High-Performance and Standard Rubber Tubing, Custom-Extruded or Mandrel-Wrapped Flexible Rubber Tubing.

Fabrication Capabilities:

Assembly, Cut-to-Length, Slitting, Coiling, Socket and Flared/Belled Ends, Heat Splicing, Special Braiding. Tube Fittings, Hose Crimping, labeling, and pressure testing available.

Materials:

Pure Gum, Neoprene, Nitrile, EPDM, SBR, Silicone, Viton®, Prince Panacea® Specialty Compounds.